Question

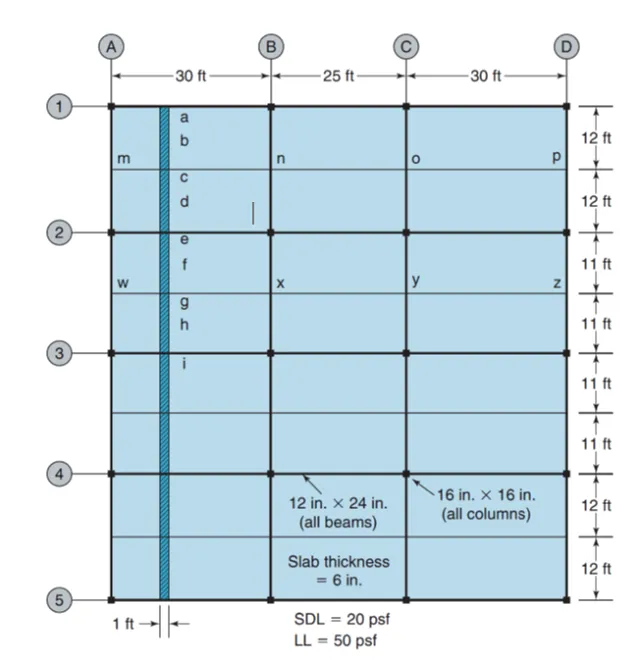

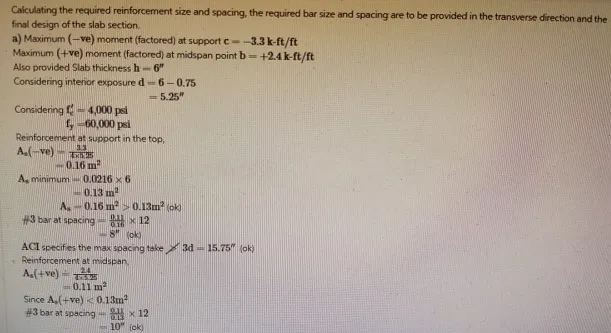

For the one-way slab shown in the figure, assume the maximum negative moment at support c is -3.3 k-ft/ft and the maximum factored positive moment at midspan point b is 2.4 k-ft/ft.

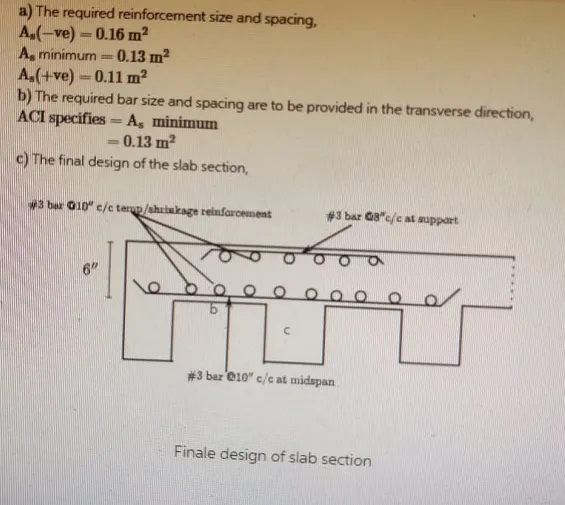

a) Using the given slab thickness of 6 inches, determine the required reinforcement size and spacing at both of these locations to satisfy ACI Code flexural strength requirements for minimum flexural reinforcement in slabs

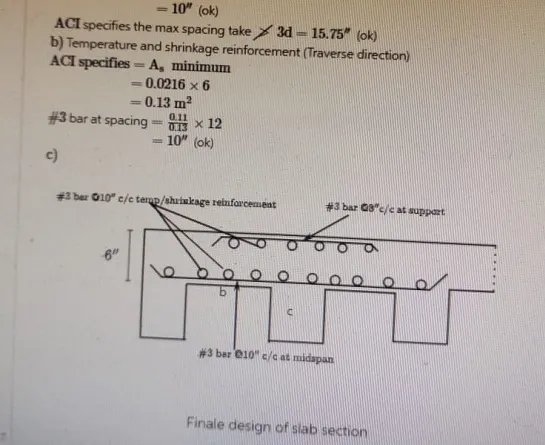

b) At both locations, determine the required bar size and spacing to be provided in the transverse direction to satisfy ACI Code Table 7.6.1.1 requirements for minimum shrinkage and temperature reinforcement.

c) For both locations, provide a sketch of the final design of the slab section.

Answer

Step 1

This thorough investigation includes the real-world implementation of ACI standards to guarantee that the one-way slab not only satisfies but surpasses the essential requirements for structural performance and integrity. To comply with strict code standards, reinforced concrete slab design and analysis are essential. The primary structural element under investigation in this work is the one-way slab, which is subject to specific positive and negative moments at the midspan and supports, respectively.

Determine,

a) The required reinforcement size and spacing.

b) The required bar size and spacing are to be provided in the transverse direction.

c) The final design of the slab section.

Explanation:

Ensuring the one-way slab satisfies the flexural strength and transverse reinforcement requirements of the ACI Code during design. In response to applied loads and climatic circumstances, the calculations and sketches emphasize structural durability and integrity, offering a practical building guide. Standard flexural design formulae can be used to calculate the necessary reinforcement. Appropriate transverse reinforcement spacing and sizing improve the slab’s overall performance and aid in crack control.

Step 2

Explanation:

While the needed bar size and spacing in the transverse direction concentrate on preventing cracking caused by shrinkage and temperature effects, the required reinforcing size and spacing address the longitudinal elements required to resist bending moments. The final design drawing helps ensure that the structural design is implemented accurately and efficiently by giving builders a visual reference.

Answer

Table of Contents

Designing One-Way Slabs: Reinforcement Requirements and ACI Code Compliance

Designing one-way slabs is a critical aspect of structural engineering, ensuring both safety and efficiency in construction. Compliance with the American Concrete Institute (ACI) Code is essential for achieving the required structural integrity. This article explores the reinforcement requirements for one-way slabs, focusing on flexural strength, shrinkage, and temperature reinforcement, as well as providing detailed design sketches.

Introduction

One-way slabs are a common structural element in many buildings, used primarily for floor and roof systems. These slabs are supported on two opposite sides, allowing them to span in one direction. Proper reinforcement is crucial to prevent failure due to bending, cracking, and other stresses. The ACI Code provides detailed guidelines to ensure that slabs are designed to withstand these forces while maintaining structural stability and durability.

In this article, we will analyze a specific example of a one-way slab to determine the required reinforcement size and spacing at critical points, in accordance with ACI Code requirements. We will also discuss the necessary steps to ensure compliance with minimum flexural reinforcement, shrinkage, and temperature reinforcement.

Understanding the Slab Design Parameters

Consider a one-way slab with the following conditions:

- Slab thickness: 6 inches

- Maximum negative moment at support c: -3.3 k-ft/ft

- Maximum factored positive moment at midspan point b: 2.4 k-ft/ft

These parameters will be used to determine the required reinforcement at both the support and midspan locations.

ACI Code Flexural Strength Requirements

Flexural Reinforcement at Support and Midspan

To satisfy the ACI Code flexural strength requirements, we must determine the appropriate reinforcement size and spacing for the negative and positive moments.

- Negative Moment at Support (c):

- Maximum negative moment: -3.3 k-ft/ft

- Slab thickness: 6 inches

- Positive Moment at Midspan (b):

- Maximum factored positive moment: 2.4 k-ft/ft

- Slab thickness: 6 inches

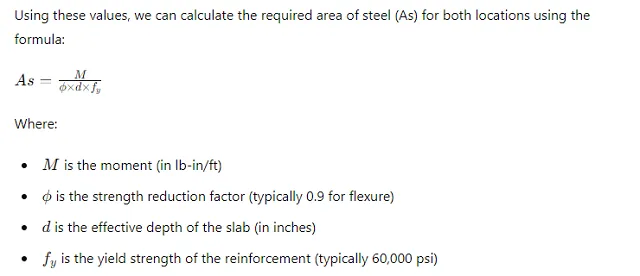

Using these values, we can calculate the required area of steel (As) for both locations using the formula:

By converting the moments to lb-in/ft and calculating As, we can then select the appropriate bar size and spacing to satisfy the required reinforcement area.

ACI Code Table 7.6.1.1 Requirements for Shrinkage and Temperature Reinforcement

Transverse Reinforcement at Support and Midspan

To comply with ACI Code Table 7.6.1.1, we must also determine the required bar size and spacing for shrinkage and temperature reinforcement.

The minimum area of steel for shrinkage and temperature reinforcement (Ast) can be calculated using the formula:

Ast=0.0018×b×hAst = 0.0018 \times b \times hAst=0.0018×b×h

Where:

- bbb is the width of the slab (in inches)

- hhh is the thickness of the slab (in inches)

Using the calculated Ast, we can then select the appropriate bar size and spacing for the transverse reinforcement.

Final Design and Sketches

Reinforcement Design Sketches

To illustrate the final design, we provide detailed sketches showing the reinforcement layout at both the support and midspan locations. These sketches include:

- Support (c) Negative Moment Reinforcement:

- Bar size and spacing for negative moment reinforcement

- Transverse reinforcement details for shrinkage and temperature

- Midspan (b) Positive Moment Reinforcement:

- Bar size and spacing for positive moment reinforcement

- Transverse reinforcement details for shrinkage and temperature

These sketches ensure that the slab design meets all ACI Code requirements for flexural strength, shrinkage, and temperature reinforcement.

Conclusion

Designing one-way slabs requires careful consideration of various factors, including flexural strength and shrinkage and temperature reinforcement. By following the ACI Code guidelines, engineers can ensure that their slab designs are both safe and efficient. This article has provided a detailed analysis of a specific one-way slab example, highlighting the steps necessary to determine the required reinforcement size and spacing, as well as compliance with ACI Code requirements.

Incorporating these principles into your slab design process will help you achieve optimal structural performance and durability, ensuring the long-term safety and stability of your building projects.